Category: Updates

Coffee, cakes, and community spirit filled the air at aae technologies on the 29th September as the applied acoustics team hosted a MacMillan Coffee morning, raising an incredible £270.30 for MacMillan Cancer Support!

The funds raised by the applied acoustics team will go towards supporting individuals and families facing the challenges of cancer, offering them the care and resources they need.

Thank you to all the bakers (and fakers) who contributed!

Wow, what a week! The aae team has just completed a highly successful three-day exhibitors’ stint at Ocean Business, which took place in Southampton, UK, on 18 – 20th April.

Described as the global meeting place for ocean science and technology professionals, we’re regular attendees at Ocean Business. It’s a hugely enjoyable and beneficial occasion where we get to connect with like minds and enhance our knowledge of what’s happening in the industry for the benefit of clients.

Day one got off to a great start with attendees queuing ahead of the official opening time, an eagerness which set the tone for the rest of the event. The aae team enjoyed talking to a steady stream of customers, who had been recommended to visit our stand to talk to us in detail about our equipment and to discuss industry news.

As you can see, our stand looked great – but it was the opportunity to jump aboard Solent Guardian, moored nearby, that had people excited to get on board and to watch our subsea tracking in action!

The vessel, kindly provided by Briggs Marine, a market leading provider of marine and environmental services, was mobilised with applied acoustics INS + USBL positioning system, Pyxis. Once safely onboard, attendees were treated to an hour-long practical demonstration of the technology which offers highly accurate subsea tracking with survey grade performance.

Also onboard was Klein – A MIND Technology Business, who hosted their official launch of the 4K-UHR side scan sonar.

Paul Griffiths, aae’s Business Development Manager (Acoustic Positioning), commented:

“Ocean Business is always a great way to connect with existing customers and friends, while meeting new ones at the same time. We were delighted to have so many bookings for our demo over both days and to showcase Pyxis to potential customers.”

“At the same time, customers have been reporting back just how happy they are with using the Pyxis system in very challenging conditions. Thank you to everyone who came to see us – we look forward to talking with you again soon.”

Missed Ocean Business and want to know more? Learn more about Pyxis and its application here.

Briggs Marine, a market leading provider of marine and environmental services, will provide their vessel, Solent Guardian, which will be mobilised with applied acoustics INS + USBL positioning system, Pyxis, at Ocean Business from 18th – 20th April 2023. aae technologies will be hosting demonstrations aboard the Solent Guardian for the duration of the event.

Briggs and aae will also be joined by Klein – A MIND Technology Business, who will host their official launch of the 4K-UHR side scan sonar at the Ocean Business event, and will also be providing demonstrations onboard the Solent Guardian. The Klein 4K-UHR is designed specifically to excel in Ultra-High-Resolution surveys with improved range performance and motion tolerance, produces MHz-type resolution without sacrificing range performance and offers High and Ultra-High Resolution simultaneous modes of operation with optimized range and resolution dependent configurations.

Together, the companies will collaborate to showcase the latest products and capabilities, bringing together industry experts, Project Managers and Technical Authorities all on the hunt for the products and innovations that are leading the way in the ocean technology sector.

aae technologies will be using the Solent Guardian to run demonstrations of its integrated INS + USBL positioning system, Pyxis. Building on decades of in-house experience in subsea acoustics, Pyxis takes the best of the company’s subsea acoustic tracking technology and combines it with a highly advanced MEMS-based inertial navigation system (INS) from SBG Systems. As a fully integrated, factory fitted package, Pyxis is a portable, calibration-free USBL system able to operate immediately from a vessel of opportunity or as a permanent installation, providing major advantages in accuracy and performance, as well as time and cost savings.

Briggs Marine’s five ‘Guardian’ class’ survey vessels are the ideal platforms for carrying out a wide range of nearshore and coastal survey activities. Coded to MCA Category 2 and capable of carrying up to 12 passengers, the vessels can be mobilised anywhere in the UK or further afield if necessary. Vessels are available for short or long term charter and are well proven for delivery of hydrographic, environmental, geophysical and oceanographic surveys.

Gavin Willoughby, Business Development Manager at aae technologies comments: “Ocean Business is an important show for us. It’s very hands-on and provides us with the opportunity to host dedicated vessel demonstrations in partnership with other world-class providers such as Klein and Briggs Marine. We’re looking forward to showing the capabilities of our products to new and existing clients once again.”

With omni-directional and directional transceiver options, the versatility of Pyxis makes it ideal for a wide variety of applications; from shallow water diver tracking to deeper water ROV/ AUV positioning, and towed sensor arrays such as side-scan sonars and magnetometers.

To read more about what you can expect to see at Ocean Business, check out our latest blog.

Since founding aae technologies in 1989 after spotting a gap in the subsea beacon market, our Group Chairman and Managing Director has seen the company steadily evolve from a one-man operation into a growing team of experts where everyone makes an important contribution.

Adam strikes the perfect managerial balance – overseeing all aspects of the business while trusting all staff, specialists and managers to meet the needs of our clients. And, if there’s ever an issue, everyone at aae knows they can come to Adam for advice and solutions. We caught Adam at the start of the week to get his insights into the early days of aae and how he sees the firm developing.

How would you describe your role at aae technologies?

I started the business as an engineer many years ago and I supposed it’s a shame I don’t get to do any engineering any more! It’s just one of those things where you progress away from where you started, so now I sit at a desk rather than a workbench, and piece together plans rather than equipment.

What was your vision for aae when you started in 1989?

I felt there was a gap in the market for a particular product and I’d had it in mind for a while to start my own business. The opportunity arose and so I went for it in Spring 1989. As I didn’t have children at the time, I could focus on the work and setting things up.

The first year was particularly difficult as I was still developing the products I needed to sell, but some anticipated work fell through, so I was stuck in a goat shed trying to do the best I could. When the product was ready in 1990 and I started to get sales, things began to get a lot better.

What was the first piece of equipment you marketed?

The gap in the market was for a small, high-powered transponder for positioning purposes. At the time, you either had smaller products that were very limited in range and depth, or huge expensive things that were just way overboard for what people needed them for. So, the whole idea was to create something compact and powerful.

I launched those and they started to sell reasonably well – although not immediately, of course. The whole method of marketing in 1990 was very different to marketing today. Old fashioned adverts in trade magazines with reference numbers and ‘bingo cards’ where prospects could circle the ad number and post it pack to the publishers, who would then send that enquiry back to the advertiser.

Otherwise, I started picking up the phone and calling people. Obviously, as I’d worked in the industry for a number of years, I knew a few people and initial customers were those I’d built up a relationship with.

What was your background prior to starting aae?

When I left school I worked for my father’s marine survey company, Gardline, for a year before going back to college to study an HND in electronics, which I had always enjoyed as a hobby. After that, I had a couple of short jobs before going to work at Ferranti ORE, now GeoAcoustics, for five years as a workshop engineer before setting up by myself in 1989.

How has your role changed since those early days?

Quite significantly! When I started I was doing everything – sweeping the floor, making the tea and typing the invoices, as well as building the product. Which gives you a good grounding as the business grows, as you have that experience in all the various necessary roles.

Now, I have people doing those things as part of their duties in the business. I think everybody in the company has a unique and important role to play, because if any part of the business process is missing – from typing invoices to repetitive workshop tasks or getting goods out of the door – we don’t get paid. So everyone is important. Everyone has a role to play. And if anyone has a problem, they can come and knock on the door and speak to me, and I’m not going to turn them away. As far as I’m concerned, we are very much a team, all playing to our individual strengths, skills and abilities.

Originally, I was designing the product, building it, ordering the parts, putting it together and so on. Then my first employee (incidentally still with us) joined as a technician. So my work role changed – I’ve become less important to the production process as the company’s grown and I’ve learned to delegate. I do lead, but give the managers a fair amount of autonomy. The last thing you need is an owner-manager overseeing everything down to the number of bottles of milk ordered.

What’s been your biggest highlight?

I think the fact that we’re still an independent, owner-managed business. So many firms have been swallowed up by larger organisations, but we’re still going and still profitable. That might not sound very dramatic or exciting, but it’s significant. Having the same ownership over thirty-plus years is quite unusual.

A lot of firms get bought out or taken over, often because an owner-manager gets to a certain age and they want to sell up and retire. I’m not ready for that yet – there are still lots of interesting things we can do, and I’d like the business to continue in a similar vein. Perhaps it’s because I started the business when I was 28 rather than in my forties, I still have this level of interest and energy for the company.

What’s been your biggest challenge?

Our biggest current challenge right now is keeping up with demand for certain products. This is usually a nice problem to have, but it happens to coincide with difficulties in obtaining some components. We’ve seen a tenfold increase in the price of some parts, and there are delays in getting others. Sadly, this is a worldwide problem and we expect it to continue for some time.

However, the new facility we’ve just taken on and our newly recruited staff will help us increase production, and our purchasing team are working hard to get supplies in. Fortunately, we generally operate with a high level of stock, which has given us a healthy buffer against shortages. Despite the problems, we have still been able to satisfy orders and will continue to do our damnedest to keep it that way.

“We’ve secured our position in the industry for the quality and reliability of our equipment, and also our integrity as a business in how we deal with customer service.”

Was there a defining moment for aae, when you saw a big change?

Two, in particular, come to mind. The first is when we got to about 16-18 people, which coincided with an office move. The social dynamic changed quite a lot and I found that I needed to have managers to deal with things because there’s a limit to how much you can handle at any one time.

The second was when we launched our first USBL positioning system in 2004, which was something that changed our business and people’s perceptions of us. A lot of customers had said, ‘when are you going to come up with a USBL system?’ And when it happened, it established us as a serious player in the industry.

What was most encouraging was how people looked at it but didn’t need to ask if it worked. They said, because it’s us, they knew it would. It was great to know we had that reputation, and our products and our company could be trusted.

On the back of that product, we’ve developed continually and now have a wide range of USBL systems in all market segments. We’ve secured our position in the industry for the quality and reliability of our equipment and also our integrity as a business in how we deal with customer service – ‘the customer is king’ is very much our philosophy.

Do you think technology has evolved in your favour, or made things more complicated?

Products are a lot more complicated than they used to be, definitely. But then you have to embrace new technology and look forwards.

New technology does facilitate new features and new capabilities, but everything is a lot more complex. I don’t think I would be able to start the business now if I was a 28-year-old because the products are far too complex for one person to design and make. The timing in 1989 was good for me in terms of technical knowledge – I could design and build products single-handedly – but there are very few people who would be able to do that now, as well as having the understanding of the market and the skills to get on the phone and sell them.

Very few things can be hand-soldered and made on a workbench anymore – components have got so small, you have to send them away to be made by a machine. This kind of delay is not very helpful when you’re young and hungry and have to wait for ages for a circuit board to come back, but that’s how things are nowadays in general.

What are you excited about for the future?

Firstly, the launch of our latest USBL system, Pyxis. It combines our expertise in subsea acoustics with an advanced inertial navigation system (INS), making it our most sophisticated system yet.

Secondly, as mentioned, we’ve also just taken on new premises to expand our production capacity to cope with demand. Our current workshop is full, so we’re moving things into the new place right now and looking forward to increased production next year as a result.

And finally, I’m feeling very positive about how a lot of what we do is going into service in the renewables sector instead of oil or gas. The number of sea-based wind farms going up around the world is ever-increasing, and our technology is being used to analyse the structure of the sea bed before the monopiles go in. We can’t say we’re saving the planet, but we’re fortunate the technology we have translates into that market and helps the energy industry go in the right direction.

Struggling with your existing equipment?

Talk to us today, or maybe check out our up-to-date range of sensors, beacons and other subsea equipment.

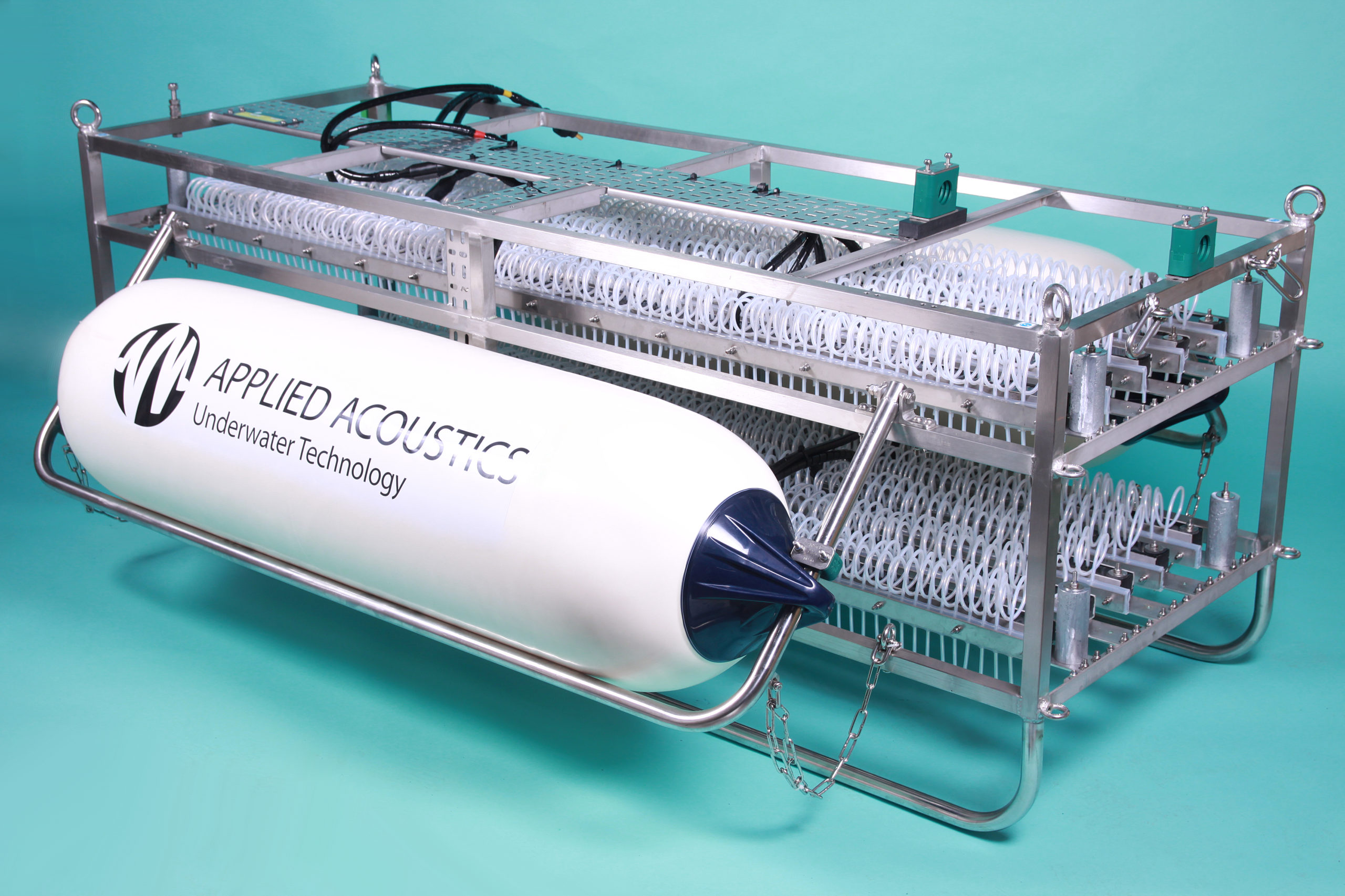

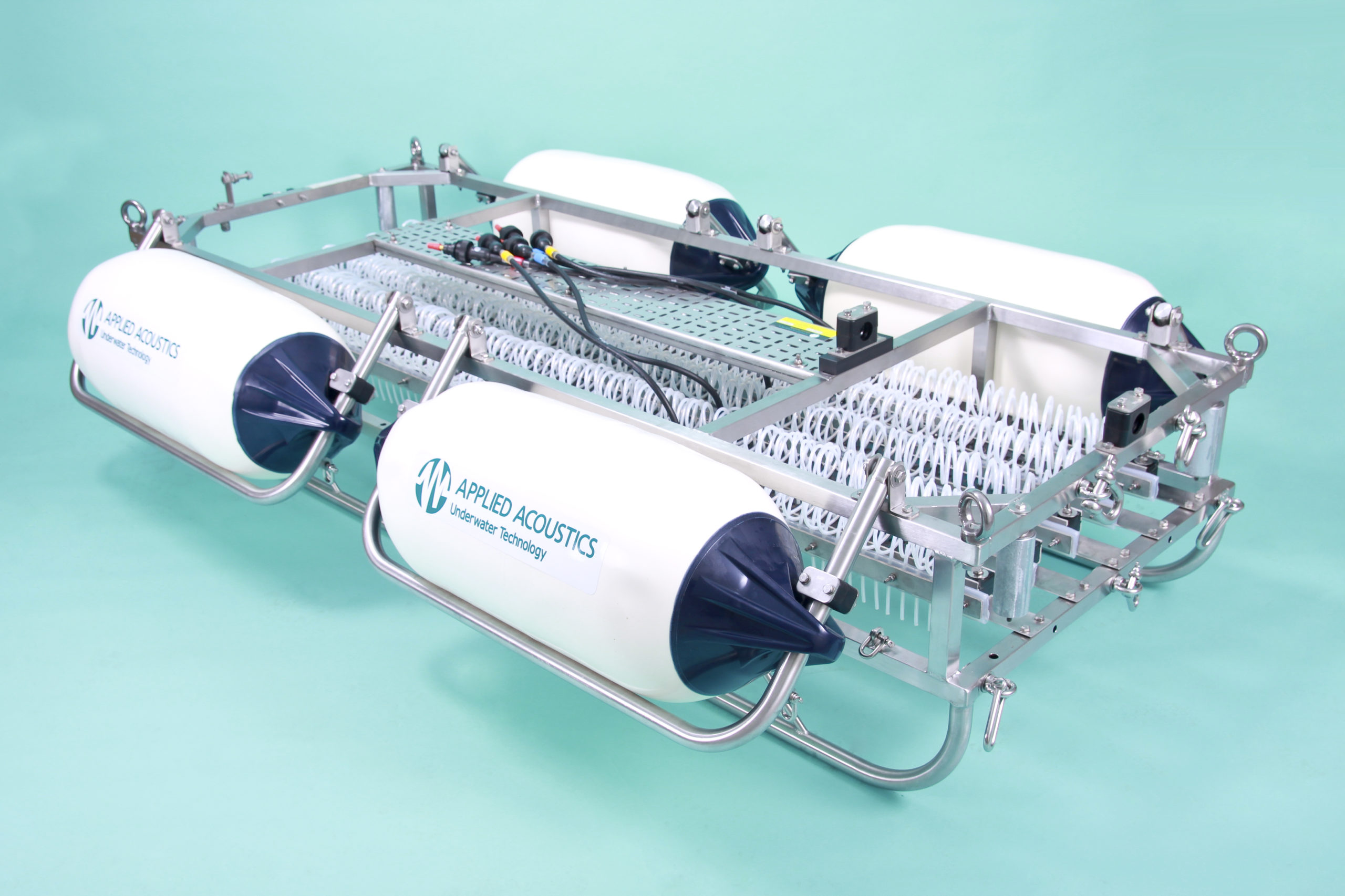

applied acoustics has announced the launch of their next generation USBL system, Pyxis USBL. Taking its name from the constellation Pyxis Nautica – the mariner’s compass – Pyxis USBL takes the best of aae’s subsea acoustic tracking technology with a highly advanced inertial navigation system (INS) from one of the most respected names in the industry, to create a state of the art, inertially aided Ultra Short Baseline system capable of accurate subsea tracking with survey grade performance.

The combination of aae’s Sigma 2 acoustic protocols and SBG Systems high precision Navsight Apogee Marine INS brings together two leading names in the field of marine technology, resulting in aae’s most accurate and long range positioning system to date, and in the process providing many time, cost and performance benefits to global survey operators.

As a tightly coupled, factory fitted package, Pyxis USBL is a portable, calibration free system able to immediately operate from any vessel as soon as the work site has been reached. The MEMS based INS does not fall under ITAR regulations, and the range restricted option means the whole system can be shipped unhindered and without export control to almost anywhere in the world. A feature of the Pyxis system is the ability for the operator to deactivate the range restriction in the field under an export-controlled regime.

A spokesperson for SBG Systems commented “aae and SBG Systems have collaborated for several years on different projects and have established an excellent relationship. We are thrilled that applied acoustics has selected our Navsight Apogee OEM high performance system to be integrated into the first-ever USBL to embed a MEMS INS”.

Available with short range omni-directional or long range directional transceiver options, the versatility of Pyxis USBL makes it ideal for very shallow operations such as diver monitoring, for deeper applications where ROV’s and AUV’s might be deployed, and for tracking short or long range towed sensors such as magnetometers and side scan sonars.

The selection of suitable sites for offshore wind development is an extremely complex issue that takes into account many factors including water depth limitations, environmental restrictions and the potential maximum distance from onshore assets. However, one of the critical elements in site selection for these installations are geological restrictions, and this is an area where the expertise of applied acoustic engineering (aae) is helping to shape the landscape of the industry.

Prior to the construction of an offshore wind facility, site characterisation surveys are required to evaluate the impact of seafloor and sub-seafloor (sub-bottom) conditions on the construction, operation and structural integrity of the proposed area.

Surveys requiring the acquisition of geophysical information are typically carried out using surface towed sensors, with aae’s range of sub-bottom profiling systems leading the way in terms of data quality and adaptability. aae’s boomer and sparker systems are being utilised to collect site-specific data such as stratigraphy, sediment variability and structure, buried boulders and rocky outcrops. Geomorphological features such as faults and folds can also be detected as well as the presence of shallow gas pockets and other potential geo-hazards. The method used to achieve this is a seismic reflection technique that relies on the interpretation of reflections from acoustic impedance changes at geologic formation boundaries.

Each aae system consists of a vessel based seismic energy source (a CSP power supply); a seismic sound source towed on the sea surface (boomer or sparker); single or multi-channel hydrophone streamers that receive the reflected signals, and data acquisition and processing software. Offering a modular range of sub-bottom profiling products, aae is able to configure systems that can be used aboard any size of survey vessel and for varying conditions of geological states and water depths.

Whilst aae produces an extensive range of geological survey systems, the S-Boom triple boomer and the Dura-Spark sparkers are particularly adept in shallow waters in which these site surveys and cable route surveys are generally carried out. Four seismic sound source sparkers are available for these applications, ranging from the L80, a lightweight 80 tip sparker used extensively in very shallow areas, coastal or estuarine surveys, up to the twin-deck UHD 400 + 400, which features ‘tuneable’ twin banks of electrode tips that can provide the highest resolution data for windfarm site survey applications.

In addition to the geological information acquired with the towed sub-bottom profiler, aae also provides positional information of the hydrophones through the use of 101G MiniPod submersible GNSS receivers. The MiniPods can be installed on the head and tail buoys of the hydrophone streamers to confirm their precise position enabling geo-referencing of the geological data.

When integrated with geo-technical results from core samples, borings and data from bathymetric and other surface condition surveys, the data collected using aae sub-bottom systems provides a key insight that ultimately helps to determine the suitability of proposed offshore installations, helping to create and sustain the future of renewable offshore energy.

As applied acoustic engineering (aae) has always known, industry diversification and changes in standards and practices, often necessitate an adjustment in the outputs of associated technology providers. The award winning manufacturer of marine geophysical survey systems long ago identified the shift in business activities of its core customers from traditional offshore oil & gas projects to the burgeoning global offshore wind industry, and has spent time channelling their experience in marine survey practices to remodel and enhance their product portfolio to better serve the needs of this industry. Realigning the highly regarded range of Dura- Spark geophysical sound sources, the UK based company now offers a complete array of systems in tune with the specific requirements and demands put in place by the offshore wind operators.

New for 2020, two lightweight sparkers have been added to the Dura- Spark product line, complementing aae’s existing systems and creating an extended family of negative discharge sparkers. Featuring twin banks of 40 electrode tips, the Dura- Spark L80 can operate in 40 or 80 tip mode, offering energy outputs of either 100 Joules or 200 Joules per shot; ideal for very shallow areas, and coastal & estuarine surveys. Its uniquely small footprint and low power consumption makes it particularly useful on board smaller survey craft with limited deck space and minimal lifting equipment.

The Dura- Spark L200 features twin banks of 100 electrode tips that can be fired at up to 500 Joules per shot concurrently, independently, in flip-flop mode or with a combination of fire delay or split fire delay. This flexibility, together with selectable source depth, allows the sound source to be used in both shallow and deeper waters for multiple marine geophysical data gathering applications.

In service since 2016, the workhorse of the Duraspark range of sparkers continues to be the Dura- Spark UHD 240/400. These proven sound sources can be found across the globe, acquiring the high resolution seismic data required for renewable energy installations, offshore oil & gas surveys and for the research and study of areas of scientific interest. With the ability to operate at energy levels of up to 2000 Joules per shot, these are extremely flexible tools with the capability of working within many project scenarios.

Making its first appearance during the second half of 2019, the Dura- Spark UHD 400 + 400 sits at the head of the Dura- Spark family and is the most sophisticated system in the range. Consisting of twin decks of 400 electrode tips, the operator is able to tune the source from the vessel to fit the required function and data requirements. Each deck can be fired independently from the CSP power supply, in flip flop mode, combined with fire delays or a split fire delay. Utilising the fire delay functions, the signatures from the 2 decks can be combined to bubble form the acoustic signature, creating an extremely clean pulse at high energy outputs, resulting in sparker data of the highest quality and resolution.

All Dura- Spark systems from aae feature negative discharge, long life electrodes designed to provide the consistently stable, repeatable sound pulses required for high resolution sub-bottom geophysical surveys, while keeping operational maintenance to a minimum.

On 4th October the Applied Acoustics team came together to take part in the World’d Biggest Coffee Morning in aid of Macmillan Cancer Support, raising a fantastic £385.

The total was generously matched by the company, doubling the dough raised to a whopping £770! The money raised helps provide essential physical, emotional and financial support to those that need it.

Thank you to all who baked, and ate!

Continuing the celebration of 30 years in business, the Applied Acoustics family closed out the summer with a grand casino and party night in it’s home town of Great Yarmouth. Recognising some of the company’s fantastic achievements and successes of the last 30 years, it’s clear that none of this would be possible without a dedicated and talented group of individuals working together as one team.

From humble beginnings supplying acoustic positioning beacons, the company has developed in expertise and now manufactures an extensive portfolio of highly technical acoustic products for a wide variety of industries including offshore renewables, oceanographic and research institutes, offshore oil and gas and defence, and can be found in the oceans right across the globe. Some things may have changed over the past three decades, but Applied Acoustics commitment to its customers remains the same.

Here’s to the next 30 years!

Ensign Subsea Systems, a member of the AAE Technologies group of companies, is proud to announce the award of a significant defence contract by an undisclosed major naval power. Utilising the technology produced by its sister company, Applied Acoustic Engineering (AAE), the award is for the supply and support of multiple units of AAE’s Nexus 2 USBL tracking system that are be installed on the Navy’s next generation mine countermeasures (MCM) vessels. Worth in excess of £1.5m GBP, the contract award follows a long period of testing, evaluation and enhancement of the system in close cooperation with the Navy and its prime contractor, heightening the reputation of the Nexus 2 USBL as a fundamental feature within the MCM toolbox.

First launched in the early 2000’s, AAE’s USBL systems have evolved impressively over the years culminating in the latest generation Nexus 2 system, a highly accurate platform capable of operating to ranges of more than 3km and to an accuracy of 0.1% of slant range. An important feature of the Nexus 2 with great significance to the MCM community, is the system’s ability to operate at fast tow speeds of around 10 knots. It’s this ability that allows the system to be used in conjunction with high speed side scan sonars and other towed sonar arrays, crucial for military groups carrying out threat detection and other subsea surveillance tasks.

Speaking from the group’s headquarters in the UK, Gavin Willoughby, Director of Ensign Subsea Systems expanded on the company’s capability in this area. “Although several hundred of the group’s USBL systems are operating in a commercial survey environment, we have now supplied close to 250 subsea tracking systems to the global defence market; and with more than 100 of those primarily installed for MCM operations, I believe we are now the leading name in this specific area of maritime security operations. We are hugely proud to be a trusted supplier of this critical component, and with our expertise in subsea acoustics, our knowledge and background in the defence industry, and our ability to incorporate the needs of our clients into our systems, I’m confident that Ensign Subsea and its sister companies will continue in their role as a primary technology provider to the world’s naval groups”.

Applied Acoustic Engineering Ltd is excited to announce its decision to open its first location in an overseas territory. The Canadian city of Halifax, Nova Scotia, will become home to AAE Americas on May 1st 2019, when the company moves into its new office at the Centre for Ocean Ventures & Entrepreneurship (COVE), a collaborative, harbour-side facility for applied innovation in the ocean sector. The COVE site features extensive marine facilities with two large, deep-water piers, office space, workshops and laboratories.

One-in-five-jobs in Nova Scotia is connected to the ocean with the province being a hub for cutting-edge research and technology development.

Laurel Broten, President and CEO of the business development agency for the Province; Nova Scotia Business Inc. comments “We are proud to welcome Applied Acoustics. Their skills, products and capabilities are a great addition to the ocean ecosystem, strengthening Nova Scotia’s strong acoustic sector, and contributing to the growth of Nova Scotia’s reputation as a world leader in the acoustics market”.

Long serving AAE Sales Manager, Gavin Willoughby, will relocate to Canada as Business Development Manager to oversee the implementation and operation of the new venture, as well as providing sales and support services to the North & South American markets, the firmly established distributor network and the wider geographical areas of business in which the company already operates.

Speaking from the company’s HQ in Great Yarmouth, UK, Gavin commented, “This is a fantastic opportunity for Applied Acoustics to increase its market share in North America and beyond. By establishing a permanent presence in the region we will be able to provide a much more efficient service to our existing customer base there, as well as being in the perfect position to seek out and support new clients and new contracts.

“Now in our 30th year, it’s an exciting time for the company,” he continued, “with many new members of staff successfully recruited over the last 12 months and with new products and innovations firmly in the pipeline, we’re very much looking forward to the challenges and opportunities that lie ahead.”

As part of the global development strategy Hollie Moran has been appointed as Sales Manager for the EMEA region, focusing on expanding the sales of the Applied Acoustics’ equipment and continuing to build on the company’s enviable reputation of providing a first class service and high quality products into the commercial, academic and defence markets.

Ends

We have recently welcomed Hollie Moran to our sales team as the new Sales Manager for the EMEA region.

In her new role Hollie will focus on expanding the sales of our USBL positioning and tracking systems and sub-bottom profiling equipment, and supporting the company’s distributors in Europe, the Middle East and Africa where opportunities have grown significantly in recent years.

“Hollie’s experience and industry knowledge are very welcome additions to our team and will help us deliver a first-class customer service at a time when we are driving forward our global expansion strategy and building stronger relationships in new geographic market areas,” said Senior Sales Manager, Gavin Willoughby.

Hollie commented, “Having worked with Applied Acoustics for a number of years I am delighted to join the team and further develop its enviable reputation for quality products in this market sector.”