How do Ultra-Short Baseline systems (USBLs) work?

As a professional working on subsea operations, you’ll know the importance of accurately tracking underwater targets – moving or static. An Ultra-Short Baseline (USBL) system accomplishes this using acoustic positioning – but which type will be right for your job?

Understanding how USBLs work will help you find the right product for your needs. Here, we’ll look at their features and how they vary for use in different depths.

What does a USBL do?

A USBL system is a way to track the location of subsea objects in a wide range of water depths – anything from 5 to 5,000 metres or more. You might need to work anywhere from a harbour or coastline environment to a deep-sea location according to your industry and field of study or expertise.

Use cases for USBLs typically involve tracking the position of remotely operated vehicles (ROVs), autonomous underwater vehicles (AUVs), human divers, underwater structures and various kinds of equipment – fixed or unfixed. Sometimes, USBLs are also used to map the sea bed or as a method of position referencing for surface vehicles.

USBLs are popularly used by companies working in offshore wind, geologists, surveyors, the military and conventional energy companies – wherever they need to track or position assets, explore the sea bed and carry out inspections, maintenance and repairs.

How a USBL works

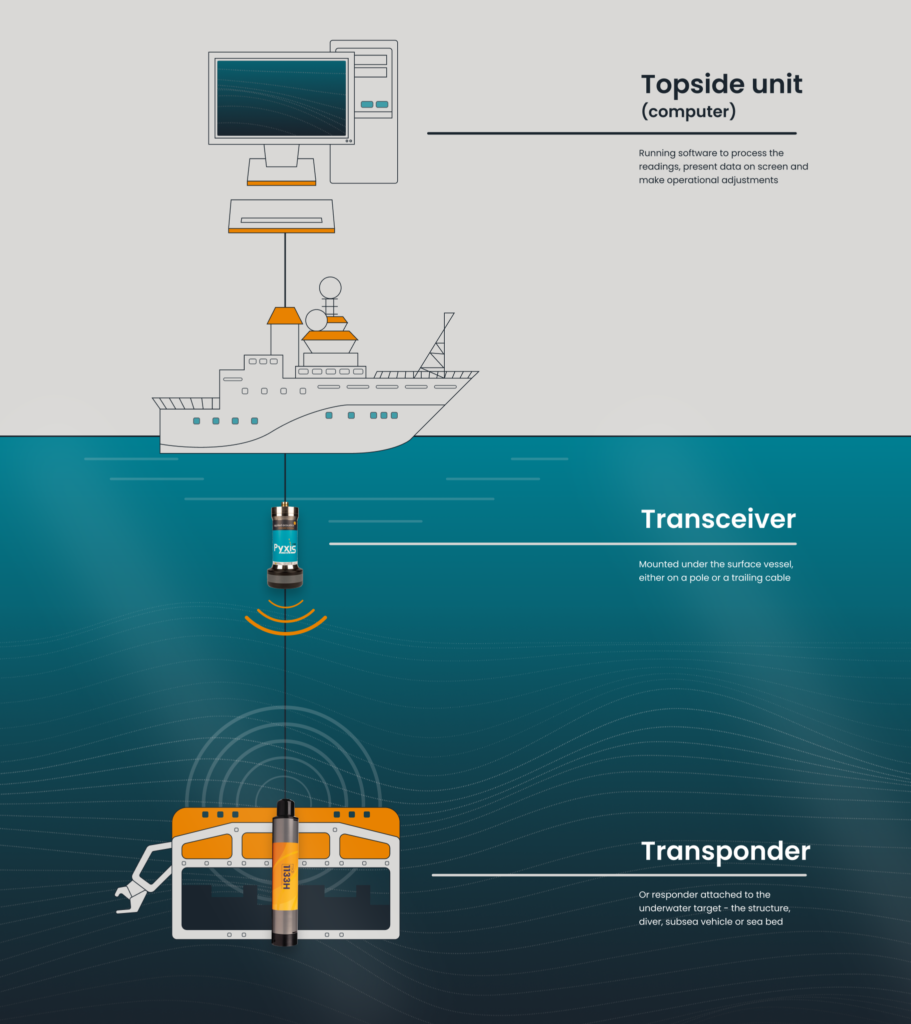

A USBL has three functional elements:

- A transponder or responder attached to the underwater target – the structure, diver, subsea vehicle or sea bed

- A transceiver mounted under the surface vessel – either on a pole or a trailing cable

- A topside unit (computer) running software to process the readings, present data on screen and make operational adjustments

The system works by the vessel’s transceiver emitting an acoustic signal, which is picked up by the transponder beacon on the target. The transponder then sends the signal back to the transceiver, and the direction of the return and the time taken for it to get back are used to determine the target’s location relative to the vessel.

Transponder beacons will vary in power, length of battery life and strength to withstand water pressure at particular depths. Smaller beacons are ideal for divers, small ROVs and short-range tracking, while their larger cousins are useful for extreme depths and longer deployment, often as reference markers.

Transceivers can vary in the size of their heads, or their array, with individual sensors separated by centimetres or by tens of centimetres. The wider the array, the more it will be able to detect the variances in the returning signal, therefore determining the bearing of the target. The simplest transceiver can track 4 targets at a time, with this rising to 10 or 16 targets for the more advanced units.

What can affect a reading from a USBL?

A USBL is, on a basic level, using sound travelling through water to determine the location of any given target. This means the actual speed of sound in water is the most important data point for all your readings – if you have an incorrect figure for how fast sound is moving through the water, then you will also have an incorrect reading for the target.

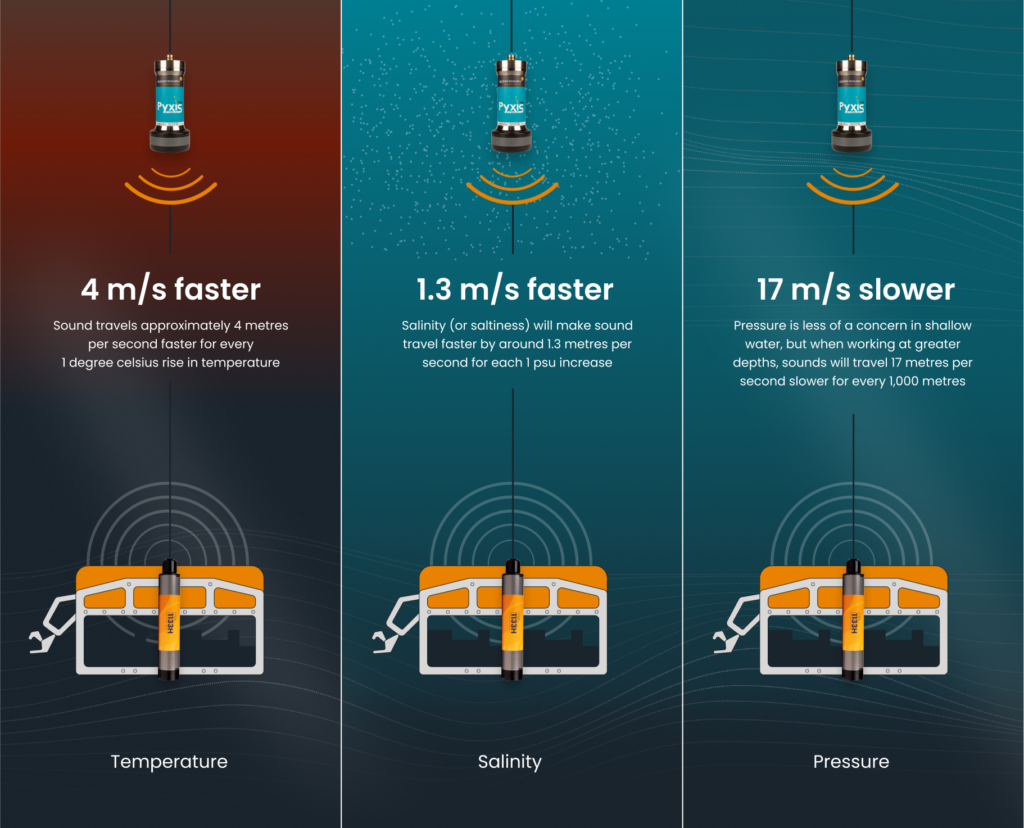

The problem is that the speed of sound through water is not constant. It will be affected by the water’s temperature, salinity and pressure – all of which must be determined and accounted for in the calculations. Water temperature will vary from the surface, where it will be typically warmer (especially if working in a hot part of the planet), to the sea bed, with the ultimate temperature dependent on depth. Interestingly, sound travels approximately 4 metres per second faster for every 1 degree celsius rise in temperature.

Salinity (or saltiness) will make sound travel faster by around 1.3 metres per second for each 1 psu increase, and can vary according to your proximity to the coast, where freshwater mixes with seawater. Pressure is less of a concern in shallow water, but when working at greater depths, sounds will travel 17 metres per second slower for every 1,000 metres.

With all this in mind, you should always take a reading with a dedicated sound velocity probe. This will account for all these factors to determine the speed of sound in the water you’re working in, and you can use the profile generated to calibrate your USBL system.

Also note that you should always position transceivers at least a metre below the lowest point of the vessel (but the deeper, the better). This is to avoid any excess vibrations on the installation from the vessel’s propeller or engine, and reduce signal reflections from the ship’s hull.

Finally, your USBL system should be integrated with both a gyrocompass and a geological survey package to compensate for the orientation of the vessel and provide a full picture of your data. Both of these are integrated as standard into aae products.

The purpose of Shallow Water USBLs

Mapping the seabed or tracking objects in shallow water (anything up to 300 metres or less) requires a different approach to deep sea projects, especially if you are working in a harbour or close to the coastline. A lot of the time, this system is used to map the seafloor and track the position of undersea structures – for example, when preparing the foundations or tether points for offshore wind turbines, or tracking divers inspecting underwater pipelines.

We cover Shallow Water USBLs in a dedicated article in this site, but perhaps the most important difference between USBLs for shallow and deep water is in the transceivers used. Shallow water means less distance for the sound pulses to travel through, so you can use an omni-directional transceiver, which will give accurate readings of up to 1,000 metres, with many able to track almost to the horizontal, making them perfect for shallow water.

The purpose of Deep Water USBLs

Deep Water USBLs are generally used during geological analysis, deep sea exploration and challenging environments. When working in deep water (anything from 300 to 5,000 metres or more), you will need to use a directional transceiver and a more powerful transponder beacon in order to obtain the most accurate readings.

Instead of transmitting a wide-angle signal, a directional transceiver focuses the acoustic pulse into a ‘cone’ of around 30 degrees. This really starts to become effective at depths upwards of 750 metres, as the further away you get from the target, the wider the area the sonic cone will cover. You will obviously need to keep targets within that cone of operation – which is fine if you are directly over your target, but can get more difficult if you are tilting your head to follow moving targets.

If working in deep water, we would recommend our MIPS 2785 and Pyxis 3780 systems – both of which can go up to 3,000 metres, and can carry directional heads.

Uses of a USBL

As mentioned, the USBL that’s best suited to your project will depend on your environment – the depth, the temperature and the salinity of the water. But it will also depend on the number of targets you need to track – the simplest USBL systems will track 4 targets simultaneously, while those with higher specifications are able to track 16 at the same time.

Typical uses for our USBLs are:

- Research vessels – particularly for survey and construction sectors, where you will need versatility for depth and temperatures.

- Position and track a remotely operated vehicle – so you know exactly where your ROV is during inspection and exploration activities.

- Tracking and communications – perfect for keeping your divers safe, especially considering how transponder beacons can stay active beyond their operational life to allow location in case of loss.

aae’s USBLs in the field

With over 700 systems currently in use across the globe, we’re grateful to have a growing number of satisfied clients who continue to take advantage of our range of USBLs’ capabilities.

Ocean Scan, based in Chile, specialises in identifying shipwrecks, pipelines, debris and underwater hazards. They integrated a Nexus 2 system and 1100 beacons with an upgraded GNSS system, basemap tools and CAD/GIS files to obtain vastly improved results in a greatly reduced time window.

“The USBL equipment allows for easy handling and a fast learning curve for its operation. Technical support has always been there when solving a problem. In general, our experience with aae has been very satisfying.”

GEOxyz provides comprehensive offshore geophysical, geotechnical, hydrographic and topographical surveys mainly to the oil, gas and renewable energy sectors. Again, their successful use of Nexus 2 and 1100 beacons has cut their survey times, improved accuracy and enabled them to deliver a better experience for their clients.

“You want your operations to be as inexpensive as possible, with as big a margin as possible and as little downtime as possible, and aae’s equipment delivers this.”

Looking to improve your survey time and accuracy?

If you’re involved with deep or shallow water operations requiring accurate positioning data for structures, vehicles or personnel, then you’ll understand the advantages of a high quality USBL system. If you have specific requirements for a particular project, our engineers will be happy to help.

In the meantime, with this knowledge of how USBLs work, take a fresh look at our Easytrak Alpha, Nexus and Pyxis USBL systems and see which might be the best for your needs.