Category: Company

The team at aae is preparing to wind down after another incredibly busy year; with team members jetting off to every corner of the globe, training being delivered worldwide, and new advancements being made with our technology and the solutions we’re pioneering for businesses within the marine industry.

Before we wrap things up for the year, we thought we’d take a look back at some of our 2023 highlights. We’d like to extend a huge thank you to all of our clients and everyone who’s been on the journey with us this year, and we look forward to sharing a number of exciting new developments in 2024.

Out and about

We’ve been fortunate to have attended some incredible events and visited many wonderful places this year. As the world continues to emerge from the restrictions of the pandemic, we’ve seen the return of a number of high-profile industry events, which have continued to deliver incredible value despite the challenges of the last few years.

We attended no less than 30 events in 2023, with Ocean Business serving as one of the main highlights. Described as the global meeting place for ocean science and technology professionals, we’re regular attendees at Ocean Business, and we enjoyed a highly successful three-day run this year, demonstrating our INS + USBL positioning system, Pyxis.

Other highlights have included further Pyxis demonstrations in Australia, subsea technology training in North America, Ocean Scan training in Chile, Nexus 2 training in Denmark, and training with the Department of National Defence in Canada.

Launches, developments and improvements

The members of our design team always have their eyes on the next innovation; continuously seeking new ways to address the needs of our clients and improve functionality in order to keep them one step ahead in their research. These include:

- The release of our 7 element omni-directional transceiver for Nexus 2 and Pyxis, as part of our Easytrak USBL product range.

- The release of our Nexus 2 Lite with a 5 element omni-directional transceiver, complete with integral AHRS, depth sensor and temperature sensor.

- The release of REL-1529P and PAM-3515, to operate with our 1500 series release beacons.

- An improvement to our Nexus 2 operating system, with user interface for Windows 10 embedded.

- An update to our MiniPod wireless protocol and receiver software in order to allow the latest RTCM corrections to be received by MiniPods.

Team news

There’s been plenty to celebrate within the aae team this year, from new joiners to milestones for long standing members. Here’s a glimpse into what we’ve been up to:

Pam Chapman celebrates 15 years

After joining back in 2008, Pam Chapman celebrated the substantial milestone of her 15-year anniversary with aae. As Group Office Administrator, Pam is one of the longest-standing members at aae and a hugely valued member of the team. Have a read of her blog to learn more about how her role has evolved over the years and what she enjoys most about working with us!

Ashleigh Mingay runs the London Marathon

aae’s Operations Co-ordinator, Ashleigh Mingay, laced up her boots back in April to complete the incredible achievement of running the London Marathon. After surpassing her fundraising goal of £2000, Ashleigh was able to make an incredible donation to the charity Mind, in honour of her own journey with mental health and the support she’s received over the years.

New faces within the team

2023 saw us celebrate the team members who have been with us for years, as well as a few fresh faces who are just beginning their journey with aae.

This year, we welcomed Tomasz Prudlack as QC Inspector, Nicole Eman as Office Administrator, and Phillip Boyne as Electronics Test Technician. They’ve all been brilliant additions to the team, and we can’t wait to see what they achieve as their careers unfold with us. Check out their new starter introductions to learn more about them.

Coming soon

We have a number of exciting launches across our product lines in 2024, as well as an exciting new office update for the aae team.

The MiniPod family is growing

A new member will be joining the MiniPod family, with the exciting addition of the MiniPod 201G. The MiniPod 200 series offers all the features of our popular MiniPod 101G series, but with additional data accuracy and greater performance in harsh offshore environments. Key features include:

- Robust GNSS receiver with integrated antenna

- Multi-band L1 + L2 + L5 receiver

- RTK Moving Base and Rover Operation

- Multi-constellation of positioning satellites

- External Sensor Integration

- Submersible, 50m rated

- Wide area corrections or external RTCM

- Assembly shock rated to 75G for field endurance in harsh conditions

- Worldwide RF remote wireless data options

Stay tuned for more details to be revealed soon!

Upgrades for the team at aae HQ

The aae team is looking forward to a snazzy office upgrade in the new year, which will include a mezzanine floor for new stock, ultimately increasing capacity for production and storage, as well as a greener energy supply with solar panels being added to the roof of our head office in Great Yarmouth, UK.

We’re really excited about how this new space will help us to grow as a business – and we’ll share some photos with you as soon as it’s ready!

A happy New Year from us all

We’re all looking forward to taking a well-earned break as the year comes to a close, but we can’t wait to get back out on the road and continue supporting our clients in 2024.

We’ll share our events calendar within the next few weeks so that we can meet as many of you as possible if you’re headed to any of these. Be sure to keep up with all of our movements and new releases over the next year – we can’t wait to share what’s to come.

For now, we’d like to wish you a restful Christmas period and a happy, healthy New Year on behalf of everyone at aae. See you in 2024!

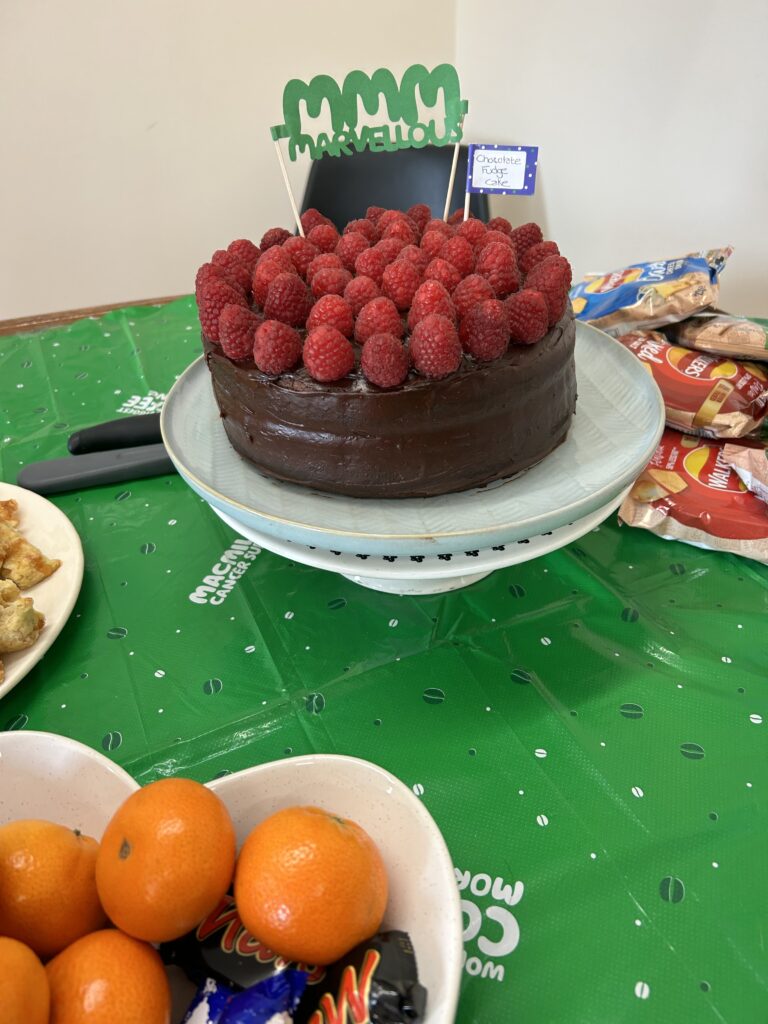

Coffee, cakes, and community spirit filled the air at aae technologies on the 29th September as the applied acoustics team hosted a MacMillan Coffee morning, raising an incredible £270.30 for MacMillan Cancer Support!

The funds raised by the applied acoustics team will go towards supporting individuals and families facing the challenges of cancer, offering them the care and resources they need.

Thank you to all the bakers (and fakers) who contributed!

Ahead of Combined Naval Event 2023 in Farnborough, aae Business Development Manager, Gavin Willoughby, looks at the benefits of autonomous underwater robotics to the defence industry and other military organisations.

Gavin, who has spent nearly twenty years supporting the development of subsea positioning technologies, continues to champion awareness of emerging technologies to combat and neutralise underwater threats.

Turning the tide on naval threats

In short, maritime defence organisations must invest heavily in autonomous underwater robotics to protect personnel. We’ve seen maritime defence organisations invest heavily and increase their dependence on uncrewed surface vessels and autonomous underwater robotics.

The role of AUVs and ROVs

Autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs) are frequently deployed for intelligence, surveillance & reconnaissance (ISR) operations, as well as anti-submarine warfare (ASW) and mine countermeasure (MCM) operations. Combined with Ultra Short Baseline (USBL) tracking systems, leveraging the right technology will save lives.

In order to protect naval personnel from potential threats, maritime defence organisations are investing heavily and increasing their dependence on uncrewed surface vessels and autonomous underwater robotics.

Benefits of USBL tracking in underwater missions

While these robotic platforms are designed to accomplish specific tasks, such as the identification and neutralisation of potential underwater threats, the successful completion of these missions depends on peripheral subsystems that can provide location awareness, accurate positional information and target guidance, such as Ultra Short Baseline (USBL) tracking systems.

When directing an AUV or ROV towards a known target and monitoring its position during the mission, an Ultra Short Baseline (USBL) tracking system can provide an effective and uncomplicated method of confirming and recording the course of the vehicle.

How it works

The coordinates of a potential target are fed into the USBL’s control system, allowing the vehicle operator to monitor its path and make necessary corrections as it heads towards its intended destination. Without a USBL system, vehicle positions would be unknown, and AUV and ROV operators would be effectively working blindfolded.

One of the more recent developments in maritime defence applications is the use of autonomous surface vessels (ASVs) from which to deploy remote subsea vehicles. ASVs further minimise human exposure to potential threats and create a further set of requirements for autonomous deployment.

Whilst AUVs and ROVs still require tracking and monitoring, this operation may no longer be carried out by operators stationed on a nearby mothership, but potentially from a crew hundreds of miles away. The use of through water acoustics coupled to satellite transmissible data allows human operators to perform their duties while remaining far from the theatre of operation.

What technologies are available now?

OEM versions of aae’s Nexus 2 USBL or MIPS 2 systems are critical catalysts in these types of operation, autonomously providing reliable and accurate subsea positioning, and then utilising radio modem technology to send the data to a remote operations centre.

While vessel-based USBL systems are still pivotal to these operations, they can only provide positional data alongside an integrated, reliable acoustic transducer on the individual vehicle. As a critical component of the system, aae makes a wide range of transducers for direct integration into AUVs and ROVs, providing clear and precise communication between the remote vehicle and its base station.

aae technologies in the defence market

Around 300 of our USBL systems have already been put to work in the defence market, with variants ranging from commercial off the shelf systems (COTS) to specially-designed OEM systems using state-of-the-art acoustic technology, engineered to meet the individual requirements of military groups and defence contractors.

However, as a provider of these key components for MCM systems, it is of fundamental importance that we remain aware of advances in the associated technology in order for us to continue innovating our products in ways that remain relevant to the industry. With potential threats becoming ever more sophisticated, it’s vital that we maintain our ongoing development programs to counter these ever growing challenges.

Whether it’s portable systems used by mobile units on small craft, integrated systems permanently installed on naval vessels or airborne systems deployed from helicopters, our engineers and wider team offer genuine expertise in an industry with a growing reliance on subsea acoustics.

Find us at Combined Naval Event 2023

To learn more about the benefits of aae technologies for underwater tracking and monitoring in defence, make sure to visit our stand on D29.

Back in 2008, Coldplay and Madonna topped the charts, we looked forward to the summer Olympics in Beijing and Barack Obama was sworn in as the 44th president of the United States. It was also the year that brought Pam Chapman to aae. Fast forward 15 years, and Pam is celebrating this substantial milestone in her career. Group Office Administrator Pam is one of the longest-standing members at aae and a hugely valued member of the team. We caught up with Pam at the start of a very busy morning at aae HQ!

Congratulations on your 15 year work anniversary, Pam!

Thank you! It’s been a very busy decade-and-a half! My main job is to support the flow of enquiries into the business while also looking after our customers and employees. As you can imagine, our phone is always ringing, and there are lots of orders on the logistics side to process. There are three of us in the team, and we work together to provide a professional service. Overall, I’ve really enjoyed every part of the role, whether that’s speaking to people, helping to provide the right information, and making sure that the logistics side all runs smoothly.

How has your job evolved over the years at aae?

A really important part of the role is handling the orders and the deliveries to our customers, many of whom are scattered around the world. Since Brexit, the rules about what you can and can’t send overseas have become pretty complicated. So, when aae arranged for me to undertake additional training in all the rules and regulations, I was pleased – even though it was a lot of hard work! In 2020, I gained the British Chambers of Commerce Foundation Award in International Trade, which covers everything from import procedures and exporting to documentation, payments and customs procedures. It’s so important to get these things right, and the training gave me extra confidence in this area.

What do you enjoy most about your role at aae technologies?

The variety. Everyone says it, but really, no two days are the same – you never know who is going to get in touch, whether that’s someone who has been to a recent event, a supplier, or one of our international customers. It certainly keeps life interesting.

What are you looking forward to as your role progresses?

It’s exciting to see the company grow, and to be a part of it. We have a really great mix of people here. On one hand, we have a really solid base of experts, all with highly specialist skills and decades of experience. Some of the team have been here longer than me! On the other hand, we’re growing all the time, which means that we have both new and young faces coming through the door. It certainly keeps things interesting and I’m proud to be part of this brilliant team.

Keep up with all our latest news here.

Wow, what a week! The aae team has just completed a highly successful three-day exhibitors’ stint at Ocean Business, which took place in Southampton, UK, on 18 – 20th April.

Described as the global meeting place for ocean science and technology professionals, we’re regular attendees at Ocean Business. It’s a hugely enjoyable and beneficial occasion where we get to connect with like minds and enhance our knowledge of what’s happening in the industry for the benefit of clients.

Day one got off to a great start with attendees queuing ahead of the official opening time, an eagerness which set the tone for the rest of the event. The aae team enjoyed talking to a steady stream of customers, who had been recommended to visit our stand to talk to us in detail about our equipment and to discuss industry news.

As you can see, our stand looked great – but it was the opportunity to jump aboard Solent Guardian, moored nearby, that had people excited to get on board and to watch our subsea tracking in action!

The vessel, kindly provided by Briggs Marine, a market leading provider of marine and environmental services, was mobilised with applied acoustics INS + USBL positioning system, Pyxis. Once safely onboard, attendees were treated to an hour-long practical demonstration of the technology which offers highly accurate subsea tracking with survey grade performance.

Also onboard was Klein – A MIND Technology Business, who hosted their official launch of the 4K-UHR side scan sonar.

Paul Griffiths, aae’s Business Development Manager (Acoustic Positioning), commented:

“Ocean Business is always a great way to connect with existing customers and friends, while meeting new ones at the same time. We were delighted to have so many bookings for our demo over both days and to showcase Pyxis to potential customers.”

“At the same time, customers have been reporting back just how happy they are with using the Pyxis system in very challenging conditions. Thank you to everyone who came to see us – we look forward to talking with you again soon.”

Missed Ocean Business and want to know more? Learn more about Pyxis and its application here.

We’re delighted to lend our support to aae Operations Co-ordinator, Ashleigh, who will be lacing up her trainers on 23rd April in a huge test of both her physical and mental strength.

As someone who’s been with the company since December 2017, it’s fair to say that Ashleigh has faced, and overcome, a fair share of challenges. From staffing changes and lockdowns, her resilience, combined with her awesome administration and people skills, makes Ashleigh a hugely valued member of the team – something that was rewarded in her recent promotion.

From the outside, Ashleigh is dedicated, professional and upbeat. But, as is so often the case, that bubbly personality hides a lifelong battle with mental health.

“Throughout my life I have always struggled with my mental health. Some days are ok and some days it’s hard to get out of bed in the morning. I am beyond lucky and grateful to feel heard and supported by the people in my life that have pulled me out of my darkest places. I know first hand the effects of mental health and also how it affects many others in my life.”

“That’s why I have chosen to take on the challenge to run the London Marathon for Mind.”

Ashleigh’s efforts are impressive, with a Strava diary that reveals weeks of training through the worst of the Great British Weather.

Ashleigh has set a fundraising goal of £2000 – which, at the time of writing, she has already surpassed! However, Ashleigh remains unrelenting in her fundraising efforts and welcomes further donations in order to support the charity’s work.

“Thank you to everyone who has donated so far – your generosity means so much to me. Any further donations to help me smash this target would be greatly appreciated. With your help we can help many people suffering with mental health. Thank you so much.”

To track Ashleigh’s progress on Strava, and to donate, visit Ashleigh’s JustGiving page.

Briggs Marine, a market leading provider of marine and environmental services, will provide their vessel, Solent Guardian, which will be mobilised with applied acoustics INS + USBL positioning system, Pyxis, at Ocean Business from 18th – 20th April 2023. aae technologies will be hosting demonstrations aboard the Solent Guardian for the duration of the event.

Briggs and aae will also be joined by Klein – A MIND Technology Business, who will host their official launch of the 4K-UHR side scan sonar at the Ocean Business event, and will also be providing demonstrations onboard the Solent Guardian. The Klein 4K-UHR is designed specifically to excel in Ultra-High-Resolution surveys with improved range performance and motion tolerance, produces MHz-type resolution without sacrificing range performance and offers High and Ultra-High Resolution simultaneous modes of operation with optimized range and resolution dependent configurations.

Together, the companies will collaborate to showcase the latest products and capabilities, bringing together industry experts, Project Managers and Technical Authorities all on the hunt for the products and innovations that are leading the way in the ocean technology sector.

aae technologies will be using the Solent Guardian to run demonstrations of its integrated INS + USBL positioning system, Pyxis. Building on decades of in-house experience in subsea acoustics, Pyxis takes the best of the company’s subsea acoustic tracking technology and combines it with a highly advanced MEMS-based inertial navigation system (INS) from SBG Systems. As a fully integrated, factory fitted package, Pyxis is a portable, calibration-free USBL system able to operate immediately from a vessel of opportunity or as a permanent installation, providing major advantages in accuracy and performance, as well as time and cost savings.

Briggs Marine’s five ‘Guardian’ class’ survey vessels are the ideal platforms for carrying out a wide range of nearshore and coastal survey activities. Coded to MCA Category 2 and capable of carrying up to 12 passengers, the vessels can be mobilised anywhere in the UK or further afield if necessary. Vessels are available for short or long term charter and are well proven for delivery of hydrographic, environmental, geophysical and oceanographic surveys.

Gavin Willoughby, Business Development Manager at aae technologies comments: “Ocean Business is an important show for us. It’s very hands-on and provides us with the opportunity to host dedicated vessel demonstrations in partnership with other world-class providers such as Klein and Briggs Marine. We’re looking forward to showing the capabilities of our products to new and existing clients once again.”

With omni-directional and directional transceiver options, the versatility of Pyxis makes it ideal for a wide variety of applications; from shallow water diver tracking to deeper water ROV/ AUV positioning, and towed sensor arrays such as side-scan sonars and magnetometers.

To read more about what you can expect to see at Ocean Business, check out our latest blog.

This spring, we’re delighted to welcome a trio of new starters to the aae team. Tomasz Prudlak joins as QC Inspector, Nicole Eman as Office Administrator and Phillip Boyne as Electronics Test Technician. Together, they’re bolstering our team across all areas of the business to help us create even better products and services.

Tomasz Prudlak – QC Inspector

Tomasz joins aae to take the role of Goods Inwards QC Inspector, a role that he’s been working towards over the last few months. Tomasz worked side by side with his predecessor who has since retired, enabling years of knowledge to be shared and enhancing Tomasz’s already proficient skillset.

“We’re really glad Tomasz has joined our quality control and material handling team. He’s brought an extremely positive attitude and work ethic with him, fitting in well with everyone he works with. It’s great to see Tomasz progress, and we have every confidence that his career will develop further as the company grows.” James Eman, QHSE & Logistics Manager

Tomasz says:

“I’ve enjoyed working at aae since the day I joined. The team is nice and friendly, and there’s a family atmosphere which makes it a pleasure to work here. I’m also really happy that I can develop my skills within the company.”

Nicole Eman – Office Administrator

Nicole began her career in hospitality prior to joining the aae team. Today, she uses her brilliant organisational skills to look after our clients’ needs, and applies her understanding of manufacturing processes to ensure that things run smoothly internally.

“Nicole is a great addition to the team, and has settled in really well. Supporting the wider business within the administration team is a challenging, multi-faceted role, which Nicole has risen to admirably. She has a positive outlook and a great sense of humour, and is already a highly valued member of the department.” Hollie Moran, Sales and Marketing Manager

Nicole says:

“Everyone at aae has made me so welcome and I feel part of the team already. I’m really enjoying working here and look forward to what my future at aae has in store.”

Phillip Boyne – Electronics Test Technician

Phillip joins aae as the result of a career change. Originally pursuing an electronics qualification as a hobby, he has now made it his full time job.

“Phillip shows admirable determination to grow his career, and together we are working to ensure that he has the knowledge and skills to thrive in his role as Electronics Test Technician. In just a few short weeks, it is clear that Phillip has great potential and is a wonderful fit within the production team.” Rob Whiting, Production Manager

Phillip says:

“From my first day, I have felt very welcome. I’m working with a great team who have shared their knowledge and experience to help make my first few months pleasant and enjoyable. I am looking forward to getting involved in more of the interesting work we do and contributing to the company’s success.”

Connect with the aae team

The team at aae technologies brings a wealth of experience in electronic, mechanical and acoustic engineering, as well as geophysics, software and computer-aided design. Meet the Experts to learn more about the aae team and connect with them on LinkedIn.

Despite the challenges of the pandemic, the struggling economy and the turbulence within the logistics industry, aae technologies has continued to swim against the current and deliver exceptional results; pushing the boat out with new products and pioneering new solutions for the marine industry.

That said, 2022 has been a testing time for all industries, with rising costs and logistical issues in the supply chain impacting lead times and cost rises. We have been working hard to mitigate this by diversifying our supply chain network, vastly increasing stock quantities on order and committing to holding more systems, where possible, on the shelf ready to be shipped.

For now, we hope that you enjoy reading our roundup of 2022 – thank you once again for your support, and we look forward to sharing more exciting innovations in 2023.

Launches and developments

Our design team has been busy pushing new innovations, addressing clients’ needs and updating functionality to keep our clients ahead of the curve. These include:

Easytrak USBL upgrades

Earlier in the year we updated the accuracy and performance of our entire Easytrak USBL product offering, including a redesign of the Nexus 2 and Pyxis omni-directional transceivers, which now boast 7 internal elements instead of the previous 5.

Launch of BluFin

Autumn also saw the launch of this cool pocket-sized device with Bluetooth connectivity, which gives customers the freedom to charge and configure 1100 and 1000 series Mini beacons on the go, replacing the 1082 Smart Switch charger.

Milestone defence contract

We were delighted to sign a contract for the supply of multiple MIPS 2 USBL systems to a major defence client – not least because it represents the 300th USBL system assigned to military service.

New MiniPod Submersible GNSS receiver developed for major construction client

A large construction company has purchased a number of re-engineered MiniPods and high accuracy submersible inclinometers to be used on a large wind farm installation project. These newly developed MiniPods and inclinometers are to be used for accurate tower installations including GNSS derived heading and inclination.

The re-engineered MiniPod is able to use corrections from each other to calculate inclination and heading between the MiniPods, as well as wirelessly transmit positioning data and receive RTK corrections. The secondary high accuracy inclinometer will pass data to the MiniPod, which will also utilise the wireless network to give the accurate pitch and roll of the platform to the survey team.

Significant order received for modified 1559 release beacons

An offshore engineering client, specialising in lifting and handling solutions, has placed a large order of acoustic release beacons for a project commencing in spring 2023. The re-engineered 1559 release beacon includes a large rope bucket and 40m length of rope.

The whole unit – which includes flotation collars – is designed to fit on an engineered platform and acoustically release, bringing up the 40m of rope which will be attached to a much larger umbilical.

The umbilical is a large piece of the final phase of the project and is imperative that it’s returned safely to the surface to ensure project completion. The 1559, which uses the same acoustic design as our popular 1519 release beacon, is designed specifically for long deployments (up to 5 years at sea) and is rated to 250kg working load limit (WLL).

Coming soon

We will be launching new systems across all product lines in 2023, further enhancing our acoustic positioning, geophysical and submersible GNSS range. Stay tuned for further information!

New joiners

As the world continues to focus its energies on renewable energy, we’ve needed to bolster our team to keep up with demand. We’re pleased to have made four fantastic appointments in 2022, representing expertise across the breadth of our production and delivery.

Andrew Watts joined us as a Design Engineer, Jordan Phillips as Purchasing Assistant, Tomasz Prudlak as Quality Control Inspector, and Nick McClean as Assembly Technician, we also have a number of new appointments lined up in the new year.

Movers and shakers

Adam Darling, our Group Chairman and MD, was honoured to attend a private lunch in May at Canada House, London, hosted by The Honourable Tim Houston, Premier of Nova Scotia. The objectives of the lunch were to celebrate Nova Scotia – UK relations in the ocean-tech sector and to discuss further opportunities.

As one of only five industry-leading companies to be invited, we were very pleased to join the discussion

Closer to home, we welcomed several work experience students over the summer; and made two well-deserved promotions. Congratulations to Ashleigh Mingay, promoted to Operations Co-ordinator in February, and Bonnie Green, promoted to Purchasing Supervisor in August.

Out and about

From the huge showcase that is Oceanology to SAGEEP, WEDA to IMAGE: this year has seen a return to some of the world’s most high profile industry events, and it’s been a pleasure to connect with the global ocean tech community once again.

Our whistle-stop tour of the world took in no less than 20 events, covering UK/Europe, North America and Asia. In fact, our attendance at OSEA just last month in Singapore felt really significant, as it signalled our return to Asia for the first time since the pandemic.

We look forward to meeting many more current and future clients at similar events in 2023. We’ll share our events calendar early next year so that we can make sure to meet you in person if you’re headed to any of these.

But for now – if we don’t speak or see you before the start of 2023 – have a very Happy New Year!

The team at aae technologies would like to extend our sincere condolences to the Royal Family, on hearing of the passing of Queen Elizabeth II at age 96.

We have had the honour, and privilege, to have won two Queen’s awards; moments that have formed cornerstones in our business’ history. We are deeply saddened by the loss, and join the rest of the nation in 10 days of mourning.

We will keep you updated if changes occur to our schedule, and will adhere to national days of mourning to pay our respects side by side with our customers and colleagues.

Her 70-year reign has been founded on a warmth of character and strength of resolve. Her lifelong dedication to the people of this nation will not be forgotten.

Her sense of humour, generosity and family values are truly reflected in how we continue to do business, and we will hold these principles true to us as we navigate the future.

Later this year it’ll be a big fifth anniversary for Ashleigh, who joined us as an administrator in December 2017. She’s seen many developments at aae since that time, with staff changes and pandemic lockdowns causing her to evolve professionally and fully embrace her recent promotion to Operations Co-ordinator.

Ashleigh gets involved with pretty much every aspect of what we do here, from sales to logistics and administration. We found a few minutes within her busy schedule to learn more about her role and her personal progression at aae technologies.

How would you describe your role at aae technologies?

Very varied – which is nice! Often I won’t know exactly what I’m doing day-to-day, so I’m basically all over the place, getting involved where I need to and making things happen. But I actually really like that. On any day, I could be doing anything from accounts to sales, repairs, freight and more.

In our office, you have to know a bit about everything, because if anyone’s absent we need to cover for it. You get to learn a great deal about the business in general and understand more areas than just your own. That’s why I like it, because you’re constantly having to think about how to get around certain problems and find solutions fairly quickly. That’s what I enjoy most.

What brought you to joining the company?

I was in a job where they pushed me towards a certain role that didn’t suit my skills, and I realised my true interest and talents were in administration. When the admin role came up here, I saw from the beginning it would be quite varied and I’d be involved with a bit of everything, so I jumped at it. Admin is my area, really, where I work best.

Did you have an interest in subsea technology?

To be honest, I didn’t know a lot about it as I was younger then! It sounded interesting to me, but it’s not something you understand that much until you actually start and get into it. And then you get to know how all the products we make work, and the interesting applications they’re used for. Obviously, I don’t have a technical background, but I find it all very fascinating and love learning as much as I can.

How has your career progressed since you joined?

I joined as an office administrator, but it was getting busy at the time and they needed someone who could cover other areas and switch between accounts, admin and sales. So it’s always been varied since I started.

Since that time, it’s continued to get busier and when one or two people left that gave me the opportunity to progress, take more control and at the same time learn more about the company and the products.

So my role scaled up due to those departures and the pandemic. It was just me and my colleague Pam taking care of all the administration and switching between those roles. We look back on that and think, wow, how did we do that? We were working from home, a person down and on the phone to each other all day. For me, that was the turning point for the progression of my career, I had to step up into the role.

It feels like it happened quite naturally, because I work well with Pam. It was easy to work out what we each needed to do each day to get things done in a very organised way, and I hadn’t realised I had that in me up til that point. So I’ve learnt quite a lot about myself doing this – I’m much more confident and comfortable in the role. It helped me to push myself, which was a great thing to happen.

What’s been your biggest highlight?

I think coming back into the office after the lockdowns and everyone being here again. One of my things is being part of a team, and working from home and just being on the phone isn’t the same as actually seeing them. I think the team has grown and become stronger off the back of that experience and coming back into the office again.

When everyone was at home, you had to keep on communicating – picking up the phone instead of just popping over to speak to somebody. So I think a lot of people learned that communication is key and it’s forced people to become a bit closer, to be positive about asking questions and so on.

And, obviously, the promotion to Operations Co-ordinator – that was lovely!

What’s been your biggest challenge?

I think when we were a person short during lockdowns, it was a massive shift. The vacant role was in sales, so I had to quickly learn how to do that job thoroughly and change my whole way of thinking for the role, while also working from home and getting through my existing day-to-day work. That was challenging, but then it was also rewarding and is paying off for me now in terms of my current job.

“We’re really good internally at saying, this is urgent. Let’s turn it around and get it out of the door.”

What do you love most about the job?

I do love coming into work and being with my team. The atmosphere here is so genuine, and you do care about each other. I love the work, I like a challenge, and I like how every day is different and there are constantly things we’re trying to find out. But if you’ve got a team that you’re comfortable with, that’s the thing that gets you out of bed in the morning.

What do clients love most about what you do?

I think people like the more personal approach in our office. We’ve built great relationships with our clients and they have a sense that they know they’re going to get our attention on their issue. They know they can rely on us and they’re not going to have to wait for ages for an answer. As we’re all a closely-knit team under one roof, we can respond fast.

We’re really good at turning things around very quickly. A customer might call saying they’re in urgent need of a part, or a system, can we dispatch it today so they get it tomorrow? And we’ll be able to say we can. We’re really good internally at saying, ‘This is urgent. Let’s turn it around and get it out of the door.’

What makes aae technologies unique?

I think we’ve just got a completely different approach to everybody else. It sounds silly, but we’re genuine, nice people, and the website reflects exactly who we are.

Sometimes, you’ll see a website and wonder if it’s all 100% true, but I believe we are what we say we are. Our personal enthusiasm comes through, in a human kind of way. And it’s also true internally – people here won’t talk to you like you’re supposed to know what something is, and if it’s quite technical they’ll always find a way to explain it in human terms that make sense. I’ve never felt uncomfortable about asking questions about how things work. If you really want to know about something, everyone will have the time to help you understand, which helps me to learn and in the end do a better job.

What are you excited about for the future?

I feel like we’ve already come so far and seen so much positive change in terms of our marketing, the website and the show stand. It feels like we’re constantly elevating ourselves and rising up. So I’m excited to see what else we can do.

If you look at the difference the last few years have made to our brand, it’s exciting to think what more we can do over the next few years!

Looking to upgrade your subsea equipment?

Check out our latest range of sensors, beacons, transponders, USBL systems, workstations and more…

In many ways, Jamie is aae technologies’ best-kept secret. Rarely having direct contact with customers, and strangely absent from our website’s team pages, he’s been playing a key role in our workshops for many years. Doing everything from writing software to drilling holes, refining our testing processes and constantly exploring the best ways to get things done, he uses every one of his diverse skills on a daily basis.

Jamie took time out from his duties as Production Supervisor to talk over the highlights of his time here at aae technologies and how his work has evolved since joining us in 1999.

How would you describe your role at aae technologies?

It’s now looking after the acoustic positioning product range. So, I could be doing anything from advising one of our engineers on what to do, to putting products together myself.

We’ve recently split production into tiers, separating our sub-bottom profiling product line from our acoustic positioning product range, which includes all of our positioning and release beacons, and our Easytrak USBL systems. I look after the acoustic positioning product range, while Rob Whiting handles the sub-bottom profiling production.

What brought you to joining aae?

Twenty-something years ago, I did a work placement at another local undersea technology company called GeoAcoustics for around 18 months. When I’d finished my HND, I was then looking for a job and sent my CV around to a few similar companies, one of which was aae.

My thinking was, I knew the area (both locally speaking and in terms of the industry) and could work here for a while until I found my ‘dream job’. Someone at GeoAcoustics vouched for me and helped me get in the door. That was in August 1999. Since then, I’ve stayed here for over 23 years – it must have been my dream job after all!

Did you have a previous interest in subsea technology?

Coming through the education system, I did an OND in engineering, which involved both mechanical and electronic engineering. This was all locally – the OND was at Great Yarmouth College and then the HND at Norwich City College. I always thought I wanted to go into the CAD (computer aided design) side of things, but found myself getting into the electronics side and it kind of went from there.

How has your career changed or progressed since joining?

So, I started as a trainee, working on subsea equipment assembly for around one or two years. I then progressed to a test engineer role, and after five years then to senior test engineer where I basically ended up looking after all the test fixtures. It’s now so long ago, it’s tricky to remember! From there it’s progressed again more recently to the production side, and supervision.

How do you feel aae has changed in that time?

When I started, the company had around ten members of staff, and we’re now up to around 50, so there’s been a marked amount of growth. When you’ve been here for as long as I have, you do start to feel a vested interest in the business, and it’s been a real pleasure watching it grow from a small company to where we are now.

Twenty-three years ago, we were at the smaller Faraday Way site, literally only 500 yards away. We might not have moved very far distance-wise since I’ve been here, but as a company we’ve taken enormous leaps and bounds. I’ve been through two moves of premises, and each time the building has gotten twice as big.

What’s been your biggest highlight or achievement so far?

Probably the whole tank testing process that we do with the beacons. I’ve taken it from what it was when I started to something far more automated.

We originally had a calculator and a piece of paper, and would manually work out all the calculations for what we were measuring in the tank. Now it’s all done by computer – you can leave it for twenty minutes and it’s all done for you when you come back. It’s gone from an hour test with constant monitoring to a twenty-minute test that is click-and-forget.

To be honest, the real achievement was actually getting the company to agree to the software. It was a three-year progression, which started with saying ‘if we invest this amount, this is what we can do.’ At the time, it was a big investment for us on software but I think it paid for itself after three years in terms of the amount of time and labour that we’ve saved. We basically cut the time for testing down to a third of what it was. That’s probably my biggest achievement.

Is it true to say technology has driven the evolution of the business?

When I started there were just four computers in the entire company. And now every person in the company has at least one device, as well as all the shared terminals for testing. The improvements in technology are visible in the products as well. There are things we do now that we couldn’t have done twenty years ago, especially thanks to miniaturisation in what you can do in the integrated circuit (IC) or microchip.

When I first started, it was literally an eprom and analogue electronics, but that role is now performed by a microcontroller or ARM chip. Where it was once all analogue electronics, it’s now all done digitally. It’s really hard to describe the change, as it’s something you can’t see, it’s all done in a little black device. But it makes a big difference.

What’s been your biggest challenge?

I guess it’s been learning to have the patience to let people agree with your opinion – or not! I’m quite opinionated, and because I’ve been here for years, I believe there is a certain way of doing things. I will share my opinion, but obviously there is a structure involved and you have to be happy to let people who have more of an idea of what to do have their opinion too.

I might disagree over how something is done, but you need to trust others with their plan and follow it. You have to believe that the person you’re working with knows what they’re doing, and that you don’t always know best. On a personal level, that’s my biggest challenge.

In a team environment, with collaboration, you always need to find the middle ground and come to an agreement. Or you can give someone else’s way a try. You can always say ‘I told you so’ at the end, but there’s no point in making things more difficult than they need to be. Sometimes the only way to know for sure is to test.

This said, I can’t think of any occasions where we’ve done something that I’ve really disagreed with and it’s gone wrong!

“I love the variety of what I do. One day I could be drilling holes in a box, another day writing software or fault-finding, trying to find problems with an item.”

What’s your usual day like?

On a good day, I’ll come in, check emails, check that everyone in the team is OK and then I won’t hear anything. Everything will just proceed as normal in terms of production and testing.

On a bad day, I’ll come in, check emails and then get a million and one problems. And then you’re in problem-solving mode for the rest of the day. But that’s the good thing about what I’m doing now – no two days are the same.

Problems vary from a small scratch on a casing to needing to replace the unit to even ‘this whole thing’s on fire, what do we do?’. That did happen, but only once! There was a short-circuit on one of the test units, so we got it outside ASAP! Nothing like that has ever happened with any finished products, though.

Otherwise, everything I do is workshop-based – due to my knowledge and skill set – and I enjoy being in the thick of what’s going on there.

What do you love most about your job?

The variety of things I get to do. One day, I could be drilling holes in a box, another I could be writing software or fault-finding, trying to find problems with an item. Quite a range of activities.

This probably grows from my college experience. Back then everyone was encouraged to try a bit of everything. It seems now that colleges don’t want to do that. We’ll have conversations with people who are just out of college who maybe have done a particular engineering course but haven’t done any modules on fault-finding or even basic engineering skills like using a drill. That might be an exaggeration, but everything seems very PC-based rather than practical, which may in part be down to how health and safety in training has changed over the last twenty years. But I enjoy having a range of skills I can use every day.

What do clients appreciate most about what you do?

I would hope the reliability of it! I don’t personally get direct feedback from clients, but news does filter through from the sales and technical teams if there are issues and something we need to check or change in our processes. It’s always good to know where we can improve anything.

What are you excited about for the future?

We have some very exciting new products coming out – some I can talk about and others I can’t yet! Obviously Pyxis is a big one for us, and much talked about, but there is some very interesting stuff in the pipeline that could be potentially game-changing for us as a company. I’m sure it’ll all be announced in due course!

In the meantime, I’m looking forward to the team growing. We took on two new production staff during the last four months and I expect over the summer at least one more will be added.

It could be that we’ll see more women coming into the industry. We’ve now got two women working in production, and I know there’s another applying for a work placement with us, so there are definitely more women coming through than 20 years ago. And it does feel more open than it was.

Looking to upgrade your subsea equipment?

Check out our latest range of sensors, beacons, transponders, USBL systems, workstations and more…